The project

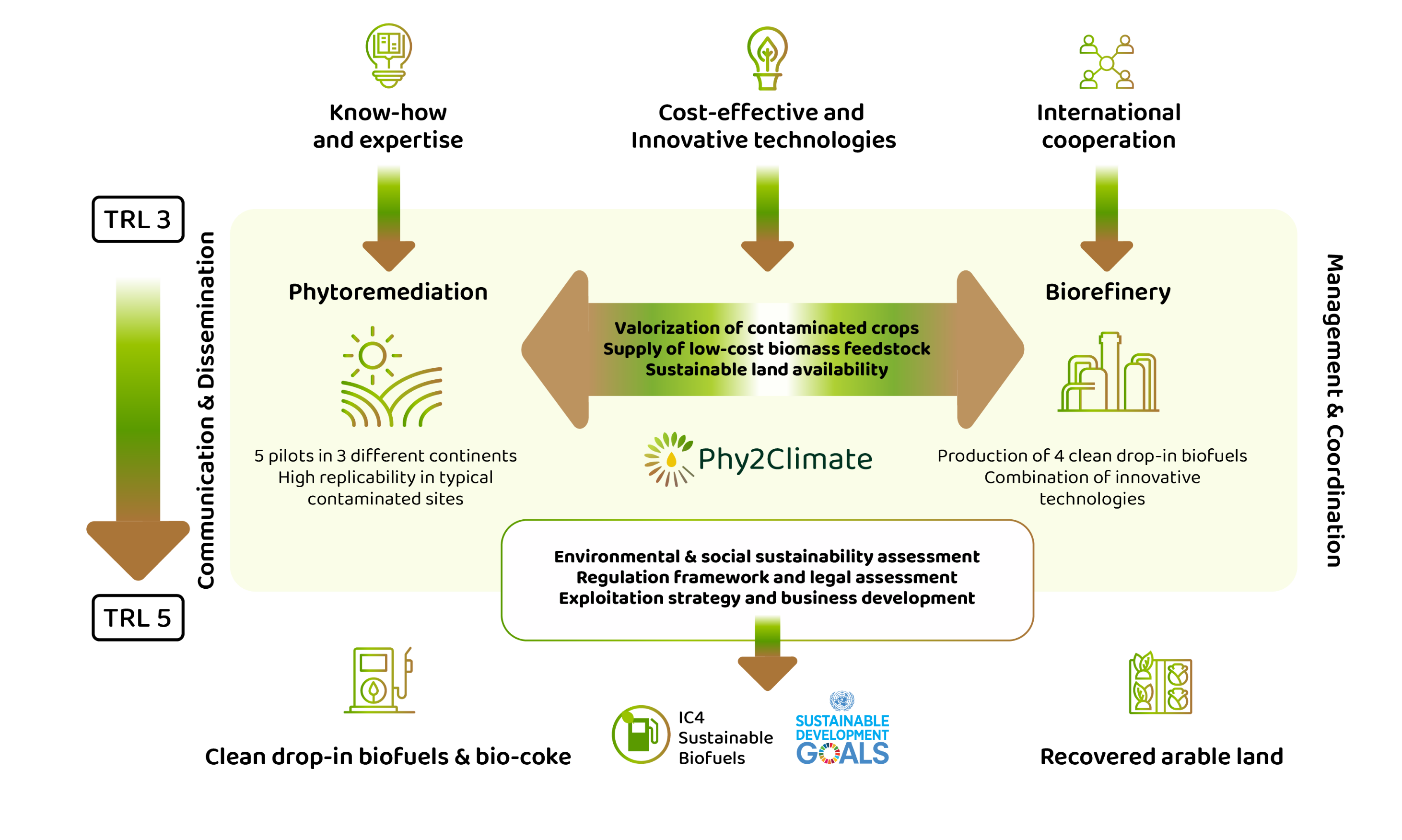

Phy2Climate is a project funded by Horizon 2020 EU’s Research and Innovation programme, aiming at combining clean biofuel production and phytoremediation solutions from contaminated lands worldwide.

Phytoremediation using energy crops

The use of energy crops as phytoremediation species is an incipient approach that is gaining interest in Europe and worldwide as an option to valorise the harvest. A high number of energy crop species that show a good phytoremediation capacity have been identified. Most of the investigated energy crops are oleaginous and lignocellulosic species.

The biofuel technologies

The Thermo-Catalytic Reforming (TCR®) combines an intermediate pyrolysis process with a subsequently catalytic reforming of the pyrolysis products. The TCR® technology shows a number of fundamental advantages over conventional thermo-chemical processes for biofuel production from contaminated biomass, such as an already proven high feedstock flexibility.

Products

The TCR® process, which acts as enabling technology in the biorefinery, produces bio-coke and the three intermediate products: TCR®-oil, TCR®-gas and TCR®-aqueous phase.

The bio-coke as substitution for pet-coke is aimed to be used as reducing agent and heat provider at the copper smelting process.

The TCR®-oil has the unique property to be distillable without the need of any pre-treatment or modification, because of its proven thermal stability. Distillate marine fuel (light fraction) and residual marine fuel (heavy fraction) will be achieved from TCR®-oil distillation fractions.

The TCR®-gas will feed the Gas to Liquid (GtL) plant. The GtL will produce methanol as biodiesel feedstock as well as diesel and gasoline as end products.

TCR®-aqueous phase will be used as hydrogen source. Hydrogen will be produced during the purification process of the TCR®-aqueous phase before being discharged in the canalization or into a regular wastewater treatment plant.

Start Date

1 January 2021

End Date

30 June 2025

EU contribution

€ 4 031 100